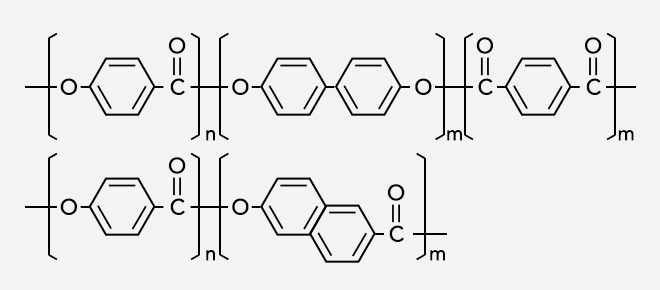

High-Performance Polymers

Junkosha focuses its innovations within the category "High-Performance Polymers". Those polymers are clearly distinguished by their excellent properties relative to other polymers.

Based on a deep understanding of each High-Performance Polymer, Junkosha applies its manipulating techniques to provide the best solution.