Junkosha Heat Exchanger

The combustion exhaust gas produced from boilers contains sulfur oxide (SOx), nitrogen oxide (NOx) and hydrogen chloride (HCl), to name a few.

Collecting waste heat in the low temperature range (200°C and below) from these exhaust gases causes severe corrosion on heat transfer tubes and housings due to the drop in the heat transfer tube surface temperature triggering condensation of the acid.

In addition, fouling caused by such things as dust deteriorates heat transfer performance, requiring maintenance to be carried out frequently.

Therefore, collecting waste heat effectively in the low temperature range was believed to be problematic.

Junkosha solves this issue by using fluoropolymer PFA heat transfer tubes with superior corrosion resistance, adhesion resistance, and heat durability.

The FLUORO-X® GRID SERIES fluoropolymer waste heat collection heat exchanger has overcome the issues of corrosion and deteriorating heat transfer performance, and achieves highly-efficient use of energy by utilizing unused waste heat effectively.

Collecting waste heat in the low temperature range (200°C and below) from these exhaust gases causes severe corrosion on heat transfer tubes and housings due to the drop in the heat transfer tube surface temperature triggering condensation of the acid.

In addition, fouling caused by such things as dust deteriorates heat transfer performance, requiring maintenance to be carried out frequently.

Therefore, collecting waste heat effectively in the low temperature range was believed to be problematic.

Junkosha solves this issue by using fluoropolymer PFA heat transfer tubes with superior corrosion resistance, adhesion resistance, and heat durability.

The FLUORO-X® GRID SERIES fluoropolymer waste heat collection heat exchanger has overcome the issues of corrosion and deteriorating heat transfer performance, and achieves highly-efficient use of energy by utilizing unused waste heat effectively.

Features

- Most advanced corrosion resistance: Fluoropolymer PFA used for heat transfer tubes on the area contacting the exhaust gas. Sulfuric acids, nitric acids, and hydrochloric acids which condense below the acid dew point will not corrode these tubes.

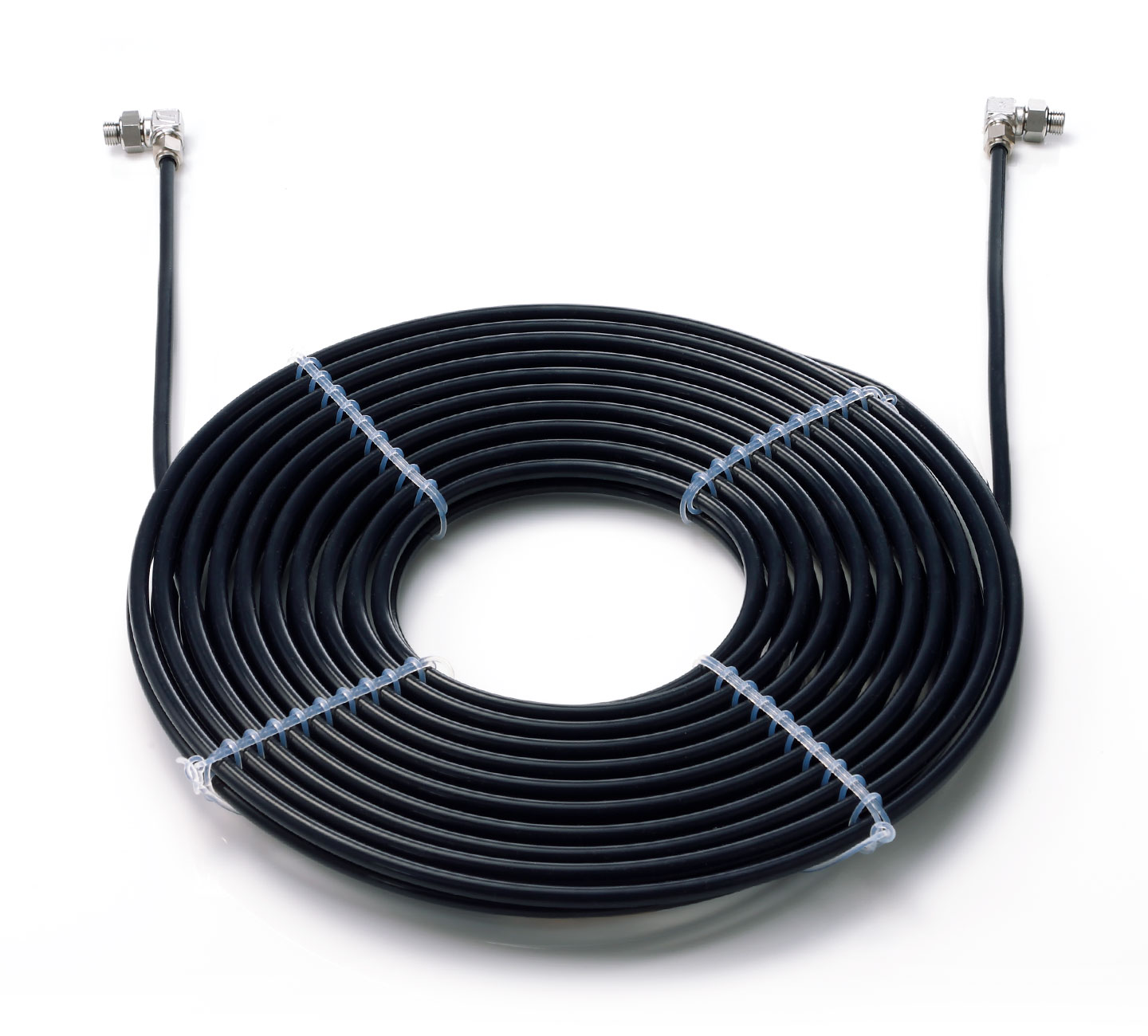

- Extremely-high heat exchange efficiency is achieved by placing narrow-diameter and thin-wall fluoropolymer tubes used for heat transfer in a highly-dense and optimal arrangement.

- The heat transfer tubes have a narrow diameter and are thin, minimizing the pressure loss on the gas side.

- The heat transfer tubes are made of flexible fluoropolymer so will not be damaged during extreme conditions such as earthquakes, and will scarcely be deteriorated in heat transfer performance due to fouling, etc.

- Fluoropolymer PFA has excellent heat stress resistance and thermal shock resistance, so will not be damaged mechanically nor through thermal shock like other materials.

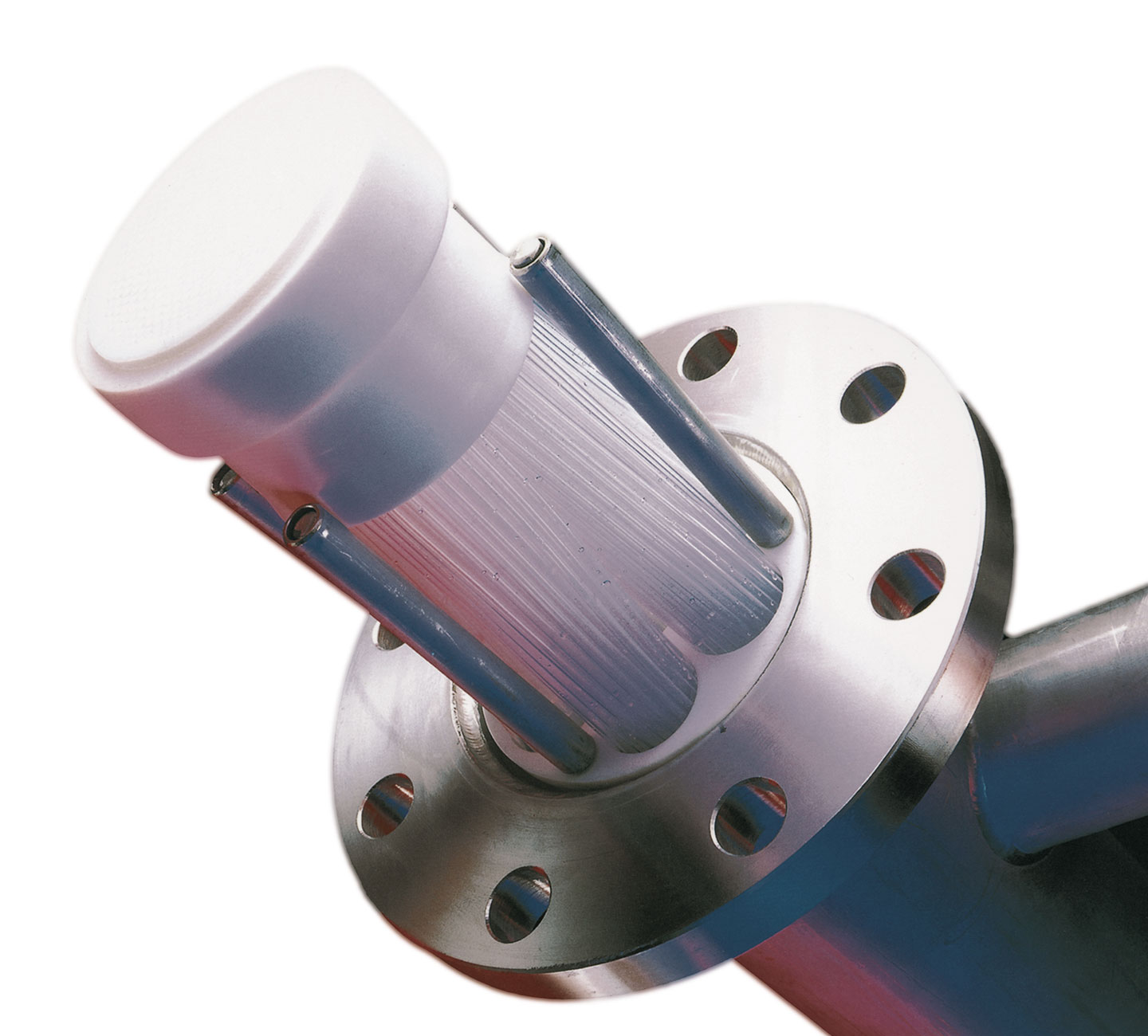

- The bundled tube ends have a honeycomb structure processed with heat sealing, and sealed areas are limited to 2 areas x the number of modules on both ends, usually between 6 and 28. Fluoride rubber gaskets are used as the sealing materials, achieving superior reliability.

- We design and manufacture the optimal system to suit a range of conditions such as specifications, installation location, and related devices.

- Extremely-high heat exchange efficiency is achieved by placing narrow-diameter and thin-wall fluoropolymer tubes used for heat transfer in a highly-dense and optimal arrangement.

- The heat transfer tubes have a narrow diameter and are thin, minimizing the pressure loss on the gas side.

- The heat transfer tubes are made of flexible fluoropolymer so will not be damaged during extreme conditions such as earthquakes, and will scarcely be deteriorated in heat transfer performance due to fouling, etc.

- Fluoropolymer PFA has excellent heat stress resistance and thermal shock resistance, so will not be damaged mechanically nor through thermal shock like other materials.

- The bundled tube ends have a honeycomb structure processed with heat sealing, and sealed areas are limited to 2 areas x the number of modules on both ends, usually between 6 and 28. Fluoride rubber gaskets are used as the sealing materials, achieving superior reliability.

- We design and manufacture the optimal system to suit a range of conditions such as specifications, installation location, and related devices.

Use

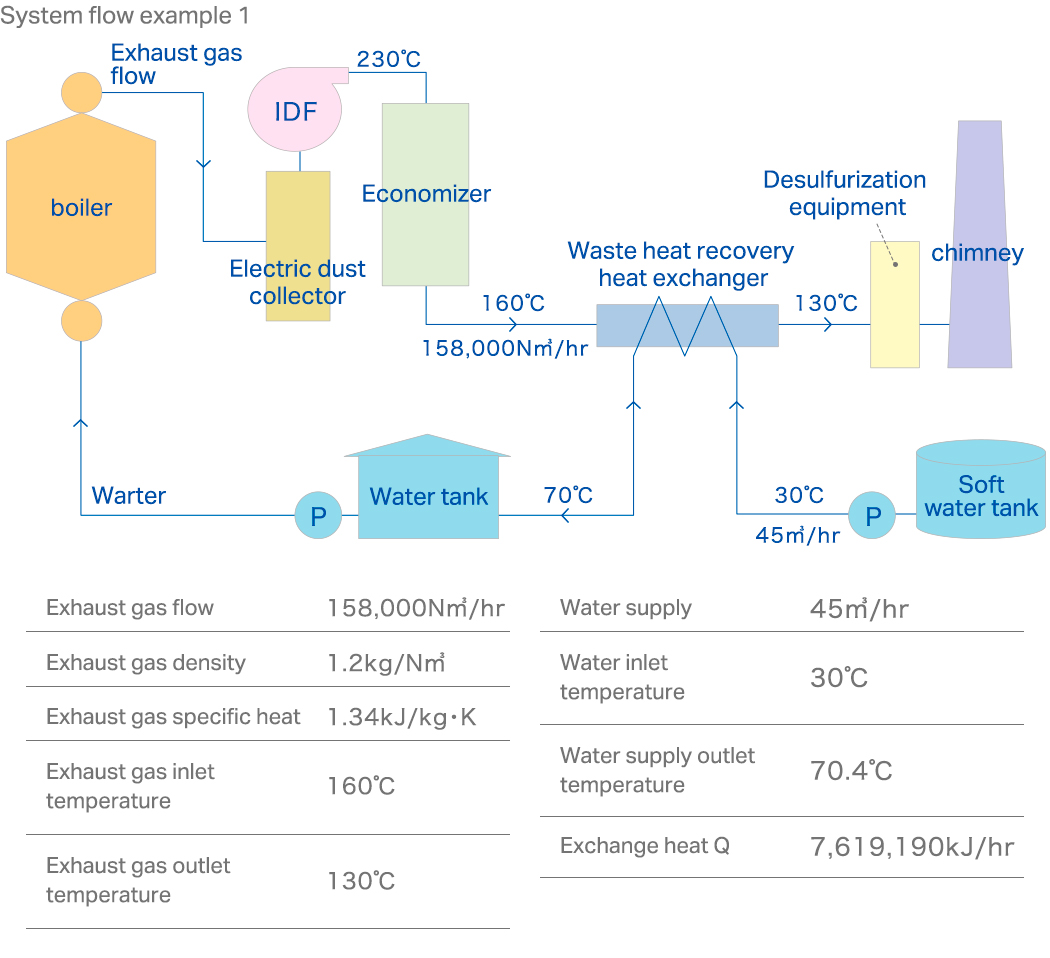

- Examples include unused heat collection from boilers (heavy oil burning, mixed fuel combustion, black liquor collection, and biomass), combustion furnaces, and drying furnaces.

- Heating from corrosive and adhering gas

- Reheating of corrosive exhaust gas before catalyst processing

- Heating from corrosive and adhering gas

- Reheating of corrosive exhaust gas before catalyst processing

| Tube Material | PFA |

| Tube Size | 3.2mm×2.4mm |

| Gas Side Pressure Loss | 1~20mmH2O |

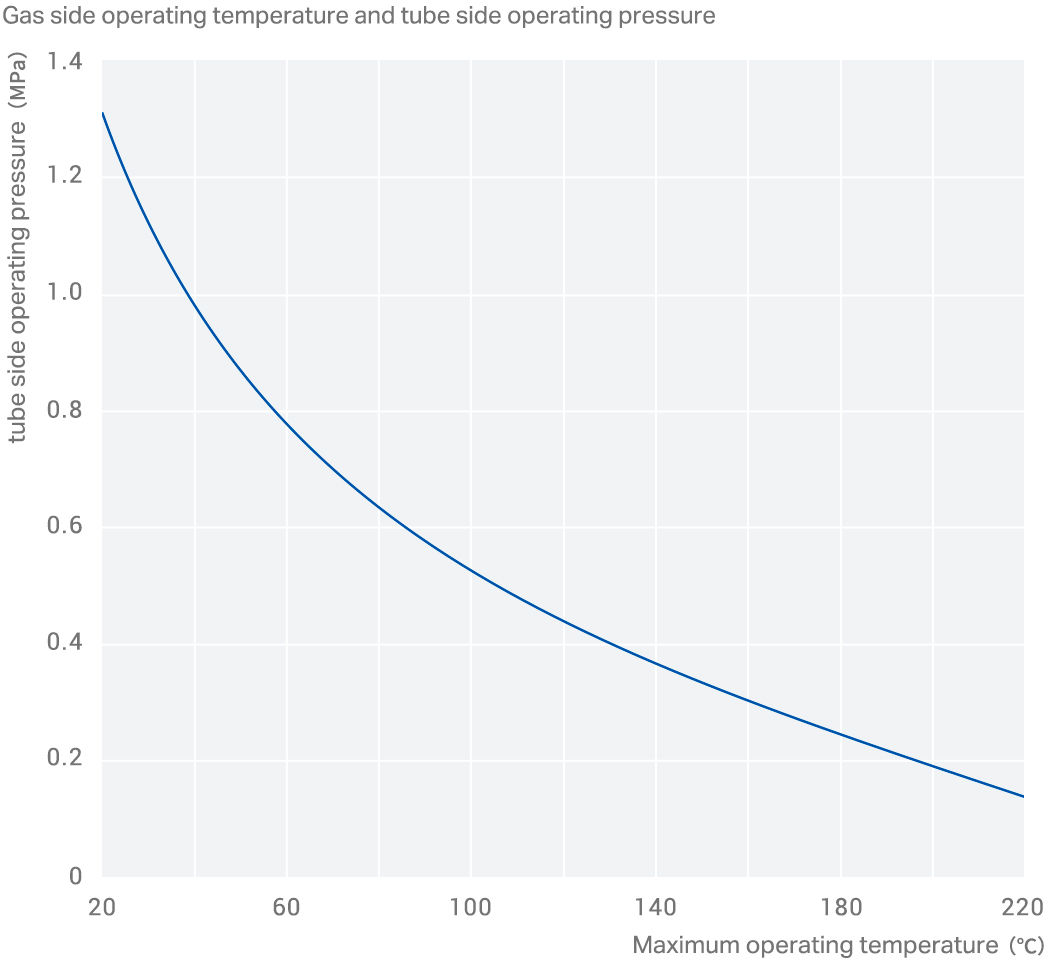

| Maximum Operating Temperature on Gas Side | 220℃ |

| Maximum Operating Temperature on Tube Side | 98℃ |

| Maximum Operating Pressure on the Tube Side (@Gas Temperature 220℃) | 0.18 MPa |

Working Pressure by Temperature

- Search for products that interest you

-