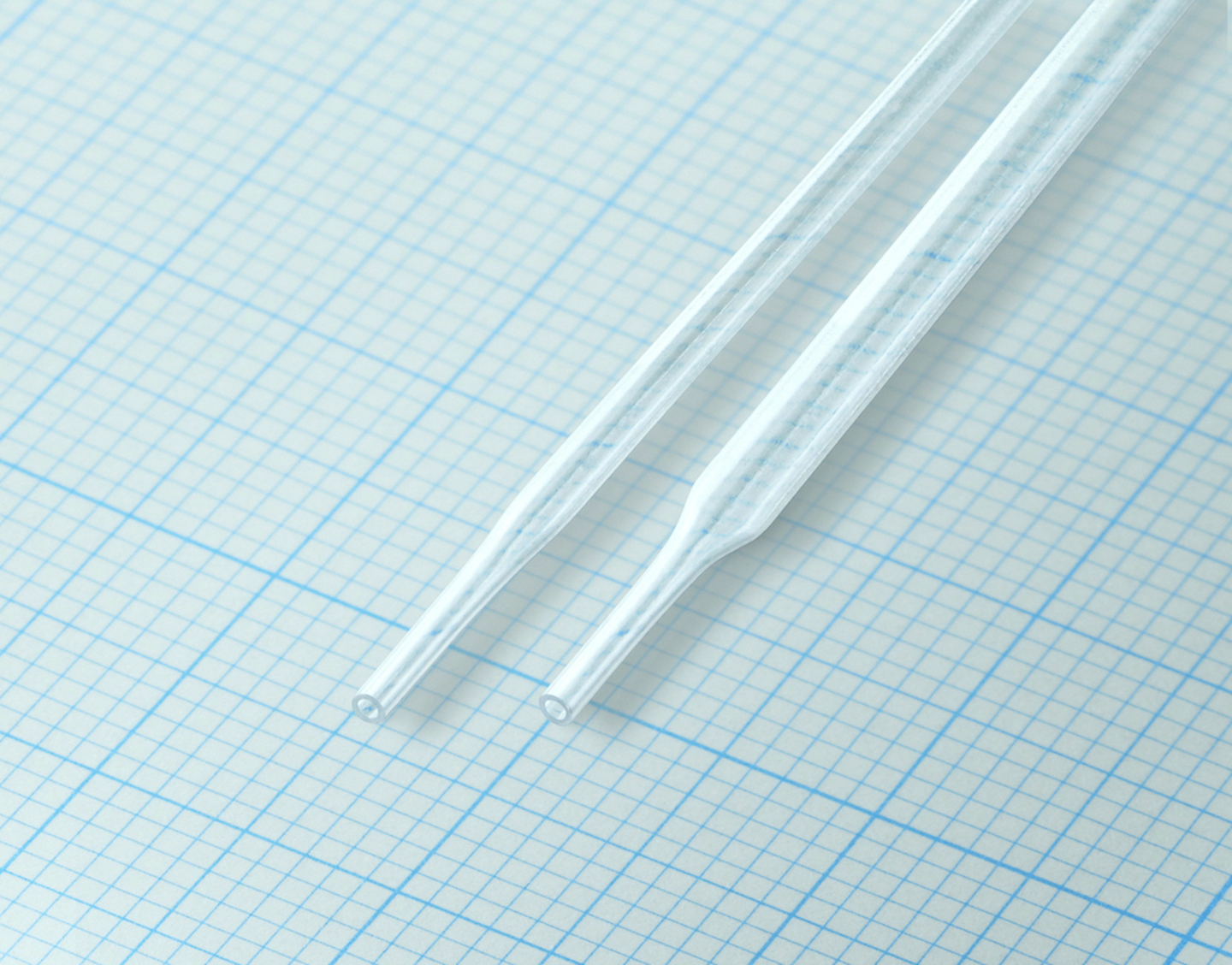

Cut-To-Length and Slit unveiled as Junkosha’s latest innovation in Peelable Heat Shrink Tubing technology

Leading heat shrink tubing specialist introduces newest peelable medical tubing solution for customized catheters suitable for minimally invasive applications

MD&M West booth number: 2492

February 4th, 2025 – Materials specialist, Junkosha, has chosen MD&M West to unveil its cut-to-length and slit Peelable Heat Shrink Tubing solution, designed to streamline manufacturing processes such as balloon bonding and reflow processing to improve product performance. Combined with its broader 2.0:1 shrink ratio offering, Junkosha is leading the charge towards heat shrink solutions that provide the flexibility needed to assemble, reinforce and integrate components of increasingly complex catheter-based medical devices.

Catheter delivery systems for functions such as balloon dilation, stent deployment, or drug delivery within the body rely on increasingly complex geometry, constructs and polymers to deliver their intended treatment. Junkosha’s cut-to-length and slit is the only peelable tubing that enables manufacturers to efficiently repair and refine components such as shafts and balloons, minimizing waste and reducing costs. The custom solution also supports precision masking during catheter coating. Unlike traditional heat shrink tubing, Junkosha’s peelable technology eliminates the need for skiving the heat shrink material from the catheter after the reflow process, reducing both the time required to take this step and also the risk of damaging the underlying catheter.

“As catheter-based devices increase in complexity Junkosha remains at the forefront by providing peelable heat shrink products that enhances reliability and manufacturing efficiency,” explains Caroline Herdman, Global Product Specialist at Junkosha. “We have a deep heritage in materials science and fluoropolymers allow us to develop solutions for challenging unmet needs in the medical device industry. With our cut-to-length and slit Peelable Heat Shrink Tubing we are providing catheter manufacturers with a way to reduce scrap rates as well as improving efficiency on the production line.”

Alongside cut-to-length and slit, Junkosha’s full range of high-shrink ratio (2.0:1) Peelable Heat Shrink Tubing will be on display. For manufacturers working with balloons, tapers or step-down components, this solution ensures tight and uniform compression even in applications involving substantial size difference. Overall, this solution has been developed with neurovascular and cardiovascular catheters and guide wires in mind where structural integrity of the device is critical.

“Junkosha is committed to meeting customer needs with exceptional service and quick turnaround times. We can support you from the initial design process through mass production,” continues Herdman. “Finally, at MD&M West, we are keen to learn more about your application needs and how our peelable heat shrink solutions can resolve your challenges.”